The manufacturing execution system can also be called the factory operation control system.

It is used to help companies from receiving orders, production, process control to product

completion, and actively collect and monitor the production data generated in the manufact-

uring process to ensure product quality. Application software.

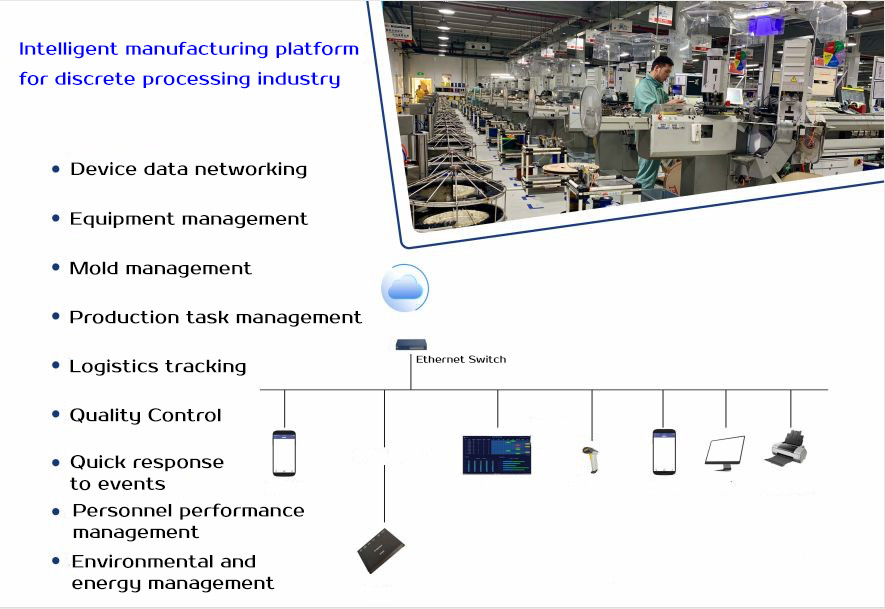

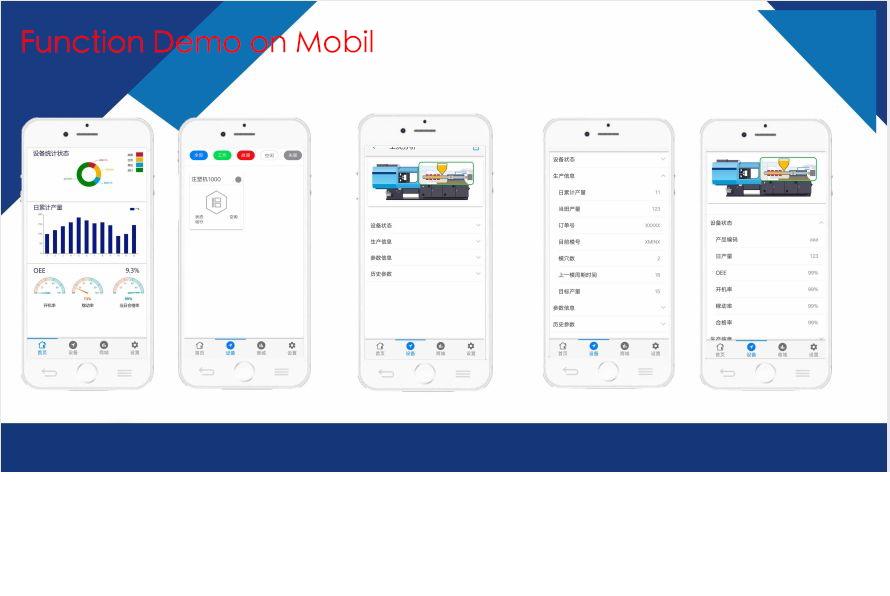

Through related database, graphical user interface, open architecture and other information

related technologies, MES can integrate the core business required by the company's

production, such as orders, suppliers, property management, production, equipment mainten-

ance, quality control and other processes. , Accurately transmit the real-time production

information on the factory production line to the user for monitoring through the Web or

other notification methods, and can also provide on-site emergency information when the

production event is an emergency, and notify the user as quickly as possible . The purpose of

introducing MES for enterprises is to reduce the impact of activities with no added value on

factory operations, thereby improving the enterprise's processes and increasing production

efficiency.

In order to meet the various needs of customers, Dihzhou Technology Co., Ltd. and Weiyuan

Software Co., Ltd. have reached a strategic cooperation. With intelligent manufacturing as the

origin and high-quality resources, they can jointly intelligent manufacturing development

needs for enterprises. Provide customers with reliable and effective service solutions!

The following is a brief introduction about the MES software functions for your reference!